Binatech Company

Our Services

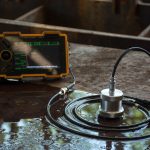

Advanced NDT Methods

Conventional NDT Methods

QA/QC Engineering Consultant

Welding Engineering Consultant

Cathodic Protection

In-Service Inspection

dedicated to providing our clients with exceptional services

Our Team

We deliver exceptional quality services through our highly qualified and skilled staff. Work coordination and training are managed by seasoned specialists with proven success in international projects. Our teams consistently achieve outstanding results across diverse assignments, showcasing both operational efficiency and professional excellence.

Our personnel are certified to Levels II, and III in multiple NDT methods in accordance with ISO, PCN, ASNT, and CSWIP standards. We also employ certified Welding Inspectors (CSWIP 3.1, 3.2.1) and professionals holding API 510, 570, 653, and 580 certifications, enabling us to perform a wide range of inspections for the oil and gas, chemical, and other industries.

All team members regularly complete health and safety training and maintain all required authorizations and approvals.

Latest Projects

From the Blog

Purpose of Reference Reflectors in Ultrasonic Testing

Why tip of crack propagates through the materials

Binatech Elevates NDT Training with Sonatest Wave Flaw Detectors

Enhanced NDT Training at TWI with Amigo2 Equipment